Back in April, as a birthday present to myself, I received a BITX40, an inexpensive 40-metre band SSB transceiver, designed by the brilliant radio amateur from India VU2ESE Ashhar Farhan.

Farhan is well-known among amateur radio homebrewers, and the BITX40 board has been purchased by thousands by enthusiasts around the world. It’s been designed specifically to facilitate experimentation, and you can find hacks and mods on the BITX20 discussion group, the Bitx Hacks site and on Github.

The BITX40 comes in a plastic dollar-store box: the bare board and some sockets, potentiometers, a tiny electret microphone, connectors and other hardware, and once the buyer solders these things on, adds 12v battery power– ‘bob’s yer uncle’– you have a working SSB rig. We call it al fresco operating.

But it’s really just a board, and it needs its own home. In keeping with the homebrew ethos of the BITX, users are designing cases and posting them. Bill Meara’s Soldersmoke blog/podcast regularly features BITX40 radios using powder-coated steel mesh, a metal popcorn box, a peppermint bark tin, and even a cakepan. Talk about retro, how homebrew can you get?

However, having a couple of months earlier bought a Prusa i3 Mk2, I thought that I’d like to design and build a 3D printed box for my new BITX.

The BITX40, being a very economical design, lacks many of the extras that grace more commercial rigs, like a signal-strength meter, CAT (remote) control by computer, or even AGC (automatic gain control). Without AGC, you can tune across the dial at weak stations and then all of a sudden be blown out of your chair by a strong station. AGC prevents that, by automatically adjusting the signal stronger or weaker, as required. Not too hot, not too cold. Just right.

So the absence of AGC requires the operator to use both hands: one for the volume control, and the other for tuning. In that sense, it’s a lot like a regenerative radio. And if you’ve read my previous post, I discovered that improper positioning of these controls can eventually get uncomfortable. Because we’re used to the conventional “dials-and-speaker-facing-front” radio case, it’s not something we’re aware of. But once you use a radio where the controls are ergonomically-placed, the experience becomes much more pleasurable.

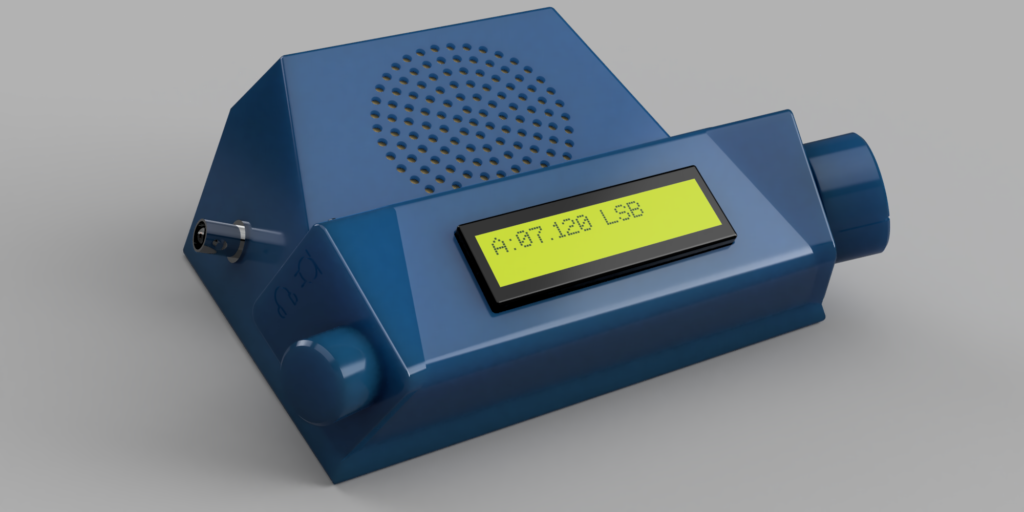

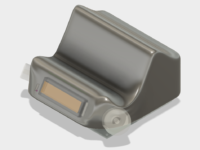

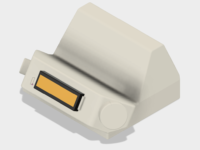

My concept is different from other box designs because it’s ergonomically more efficient–the volume and tuning dials are positioned for ease of use and the speaker is tilted up towards the operator’s head. It’s small and has a much larger heat sink to accommodate 100% duty cycle transmissions that digital modes require. The design for the BITX40 evolved over several weeks; I started just playing around with Fusion 360 without making much headway. I experimented with the Sculpt environment in 360. I found it unwieldy and went back to Modelling. I made a total of 9 false starts before settling on a final design.

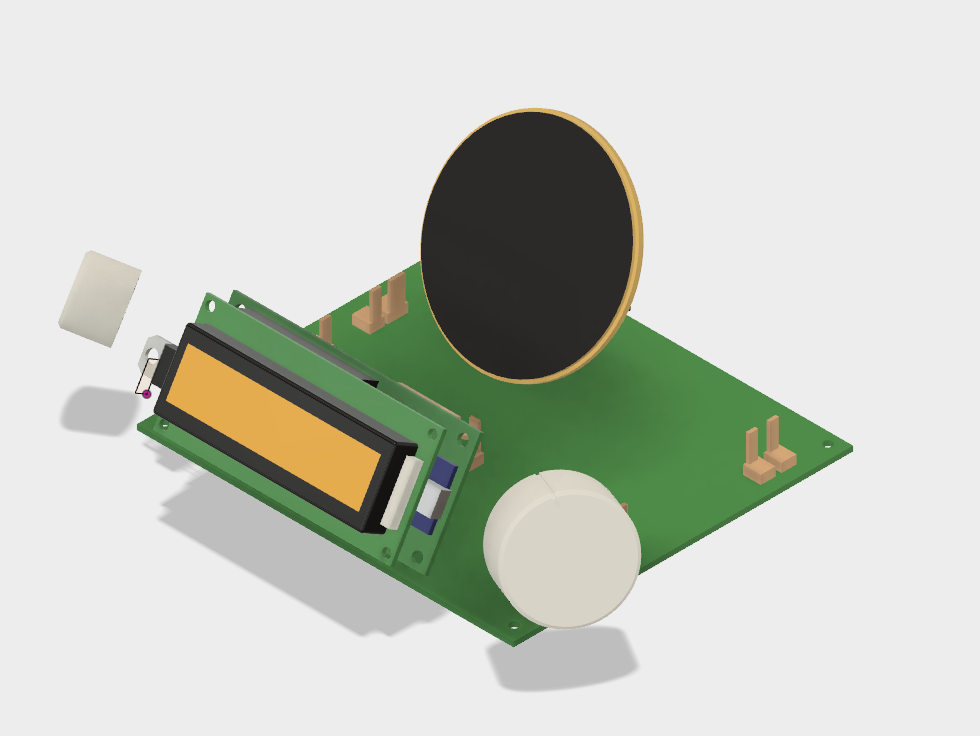

About halfway through this process, I realized that I was designing the shell without taking full account of what needed to go inside. So I modelled facsimiles of the BITX40 board and all the other components, so I created a “starting point” model from which all later models would derive:

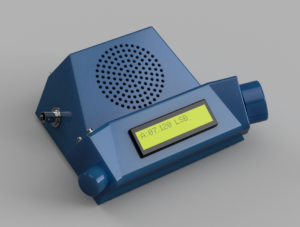

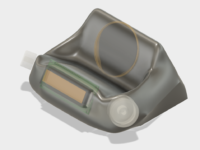

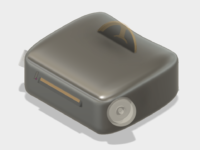

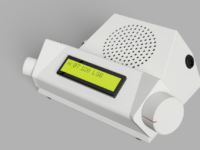

Here’s a final render of the enclosure using a translucent blue, meant to represent a PET filament that I planned to use:

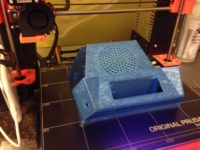

And here are some photos of the actual enclosure during printing, assembly and use:

The model is available for download on Thingiverse. I also designed a small microphone enclosure that you can also print out.

Would you sell one of these to someone without a 3-D printer or friends with one, and how much would you charge with shipping to New York. Thanks KD2NMQ