Over the past year I’ve been playing with radios. I started by building oscillators, then amplifiers, and then radios.

Regens

Radios come in all different shapes and sizes, and this also holds true for the circuits inside the radio. One of the earliest radio receiver techniques is called “regeneration”. It was devised by Edwin Armstrong in 1912 when he was still a student at Columbia. This method routes part of the received signal that emerges from an amplifying device back to the input to increase the gain of the circuit. The design was common up to the 1930’s when it was superseded by other more sophisticated methods. However, regen radios have lately had a bit of a comeback with the “internet of things”; your garage door opener receiver is likely a regenerative receiver, for example.

So I’ve been building simple regen radios for various shortwave bands. Some work, some don’t. The latest one is called a “WBR” (Wheatstone Bridge Regen). This one works. I used designs from N1BYT (PDF file) and AA7EE. This particular design is tuned by varying the voltage from a ten-turn potentiometer. My radio tunes from around 9.4 to 10 MHz.

The 10-turn pot results in smooth, very fine tuning, but it’s difficult to know what frequency in this range I’m tuned to. Many older radios have an elaborate system of pulleys and strings that link the rotation of the tuning dial to an indicator. It is possible to buy a 10-turn pot with a reduction gear. They aren’t expensive, but the indicator goes from 0-9 or some arbitrary set of numbers, not the actual tuned frequencies.

I’ve decided to see if I can use a small servo motor (one that are used in radio controlled helicopters, planes and drones) to turn an indicator dial that accurately reflects the tuned frequency.

Perceived and/or Assumed Drawbacks

I did a cursory search online to see if other experimenters had tried this, and I found nothing. Am I such a divergent thinker that nobody else has thought of doing this? I certainly don’t think so. It’s just that nobody has thought to document their discoveries.

At any rate, I’m assuming that there are several reasons why this technique hasn’t been adopted:

- Servo noise may interfere with reception. An increasingly popular method of determining tuned frequency is to add a digital display. Some digital hash may leak into the radio circuits from the display’s digital pulses, but this doesn’t stop experimenters and manufacturers from employing this method in their radios by carefully shielding the digital section from the analog. However servo noise — that is, noise generated by the motor — may be louder than the digital noise that’s produced by the microcontroller and associated digital components, and this may drown out weak radio signals.

- The servo motor is power-hungry, making it unsuitable for battery operation.

- It may be difficult to consistently align the dial markings to tuning.

- Other unknown unknowns.

Follies

My first thought was to control the servo using an Arduino. A quick sketch of the display circuit indicated that I only needed one analog input and one digital PWM output. I was able to breadboard a circuit and loaded in the “Knob” sketch that comes as an example with the Arduino IDE. Everything seemed to work well. But rather than use a larger Atmega328PU chip that has 28 pins—22 of which would be unconnected—I decided to try an ATtiny form factor. I had both an ATtiny45 and an ATtiny85 in the junk box.

I built a programming shield for the ATtinys, and managed to successfully flash the Arduino bootloader into them, but the standard Arduino servo library “Knob” sketch would not work on the ATtiny. I spent a day or so trying other libraries but it seems that there’s not been a lot of interest in overcoming this obstacle.

I went back to the junk box and found an Arduino Mini Pro. It’s overkill but it’s at least small enough to install in the radio, and inexpensive compared to an Arduino UNO. So, onto the breadboard it went: the sketch loaded and things were looking up.

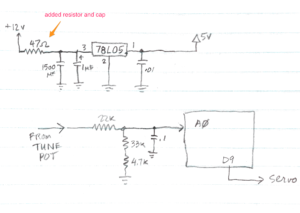

In this radio, the analog input comes from the wiper arm of the tuning pot, which goes from around 1 volt to 8 volts; the tuning section of the radio uses 8v and the Arduino Mini Pro needs no more than 5v, so I had to build a 5v supply. This signal from the potentiometer goes through a voltage divider to reduce the maximum voltage to 5v to ensure that the analog input pin is not overloaded.

One thing that I found on the breadboarded circuit was that the servo motor would sometimes draw so much current as to reset the microcontroller. This problem was mitigated (somewhat) by adding a low pass filter composed of a small resistance and a large capacitance across the input of the 5v regulator.

Building Notes

Time to build it into the radio and play with it…

LeBlanc’s Law: Wiring errors are proportional to the density of components on the circuit board.

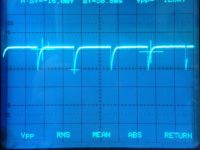

- attached to receiver: when the motor runs, it draws down the voltage very slightly which causes some receiver noise

- drawing Arduino current from +12v—does not seem to work if source comes from 8v

- watch out for LM78L05 pins: pin 1 is output and pin 3 is input!!!

- watch out for ground loops: be sure to attach Arduino ground close to Arduino +V

- ISSUE: various noises from servo

- added a 47Ω resistor in series and 1500µF capacitor in parallel on input to voltage regulator to reduce motor noise

I seem to make one particular recurring mistake when building a final circuit: I don’t use a large enough board. This happens most often when I’ve breadboarded a circuit and I think that the design is done and I can go ahead and solder everything together. But what ends up happening is that I find problems or improvements to the “final” design that then becomes quite difficult to achieve in the close quarters of a crowded circuit. That, plus the fact that wiring errors are more likely as density of components increases, caused a relatively simple task that should have taken less than an hour to take days (well, not literally) of troubleshooting.

Initial calibration was performed by feeding in signals between 9.4 and 10MHz using a DDS sine wave generator through a -30db attenuator, and locating them on the tuning dial. I’ve not done any subsequent calibrations to see if the tuning indications vary over time.

Experiment Notes

Jan 13 & 14:

As I moved the components from the breadboard to the perfboard, the device became unreliable. This may have been because I connected the servo improperly. When tuning quickly, it seemed like the controller would reset, causing hiccupping. I replaced the Arduino Mini Pro with a new one and it worked fairly well for a few minutes but it later exhibited the same issues. Could it be starved of current when the servo motor is actuated?

Conclusions

- Input voltages between 4 and 5 volts seem to make the servo hesitate and surge. This could be attributed to the 78L05–replacing it with a (higher current) 7805 regulator might fix this.

- Sometimes the servo hunts. It should be possible to turn off the servo once it has moved to the correct location.

- It’s difficult to calibrate the display. It may be possible to add trimmer resistors to the voltage divider that would permit better calibration.

- The servo isn’t completely silent and may become annoying, especially when the listener is trying to copy weak signals out of the noise floor.

- Why use a microcontroller? Is there a more “analog” circuit component that could be used instead?

- More experimentation is warranted…