A: When you work for a North American governmental environment agency.

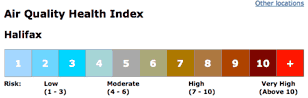

The “Air Quality Index” is used by the EPA, Environment Canada and other agencies to communicate air quality to the general public. Unfortunately, the term is counter-intuitive: in the up-means-down world of the environmental bureaucracy, the higher the number, the lower the quality! The graph attempts to mitigate the confusion by adding the term “risk”, but in doing so it merely compounds it. The result is confounding and unnecessarily complicated to understand.

The colour coding on the graph is also visually misleading: It goes from blue (cold) to red (hot). Is this a temperature graph–or does this mean the air is better when it’s colder? The graph probably should go from green (good) to red (warning/bad). Somebody should do something!

Asian countries, on the other hand, use “API” (Air Pollution Index), where higher numbers communicate higher pollution. This makes perfect sense to me, and I don’t know why our bureaucrats seek to bury the information in doublespeak, especially when we actually have better quality air than they do in much of Asia.

Here’s the explanation from Environment Canada:

Here’s what the readings mean:

- If the air quality value is 25 or less, the air quality is considered relatively good.

- If the AQI value is in the range of 26 to 50 (fair category), there may be some adverse effects on very sensitive people.

- An index value in the 51 to 100 range (poor category), may have some short-term adverse effects on the human or animal populations, or may cause significant damage to vegetation and property.

- An AQI value of more than 100 (very poor category) may cause adverse effects on a large proportion of those exposed.

Notice that the explanation refers to “fair category” (another attempt at mitigating the confusion that’s caused when you try to combine the words “high” and “quality” to convey “low quality”) but this is not expressed in the graph.

So am I missing something? Why does Environment Canada do this, other than to repeat the mistake of the EPA? Is there a scientific reason?